What Are Fiber Optics Made Of?

Fiber optics are the backbone of modern communication systems, enabling high-speed data transmission over long distances. Understanding what fiber optics are made of and how they work can help you appreciate their importance and uses. This article will delve into the materials and components that make up fiber optics, the manufacturing process, and answer common questions to help you grasp the basics of this incredible technology.

What Are Fiber Optics?

Fiber optics are thin strands of glass or plastic used to transmit data as light signals. They are essential in telecommunications, internet services, and various other applications that require fast and reliable data transfer. The development of fiber optics has changed the way we communicate and access information.

Definition and Overview

Fiber optics are hair-thin, flexible fibers that transmit light from one end to the other. These fibers can carry large amounts of data at high speeds, making them perfect for modern communication needs.

Brief History and Development

The idea of using light for communication goes back to ancient times, but the modern development of fiber optics began in the 1970s. Since then, they have evolved and improved, becoming the preferred method for data transmission due to their efficiency and speed.

What Are the Main Components of Fiber Optics?

Fiber optics consist of several key parts that work together to transmit data efficiently. Understanding these components helps in grasping how fiber optics function.

Core

The core is the innermost part of the fiber optic. It's usually made of glass or plastic and is where the light travels. The core's quality is vital for the fiber's performance.

Cladding

Surrounding the core is the cladding, a layer made of a different type of glass or plastic. The cladding reflects light back into the core, helping to keep the light signals strong and focused.

Coating

The coating, often made of polymer, protects the fiber from moisture and physical damage. It also helps maintain the integrity of the light signal.

Buffer

A buffer coating surrounds the coating, providing extra protection against physical stress and environmental factors.

Strengthening Fibers

These fibers, usually made of materials like Kevlar, add strength to the fiber optic cable, making it more durable and resistant to damage.

Outer Jacket

The outer jacket is the final protective layer. It's made of plastic and shields the inner components from the environment, ensuring the fiber optic cable remains functional and safe to handle.

What Materials Are Used in Fiber Optics?

Fiber optics rely on specific materials to ensure efficient and reliable data transmission. Here's a look at the main materials used.

Glass vs. Plastic Fibers

The core and cladding of fiber optics can be made from either glass or plastic. Glass fibers are more common in high-performance applications because they offer lower signal loss and can carry data over longer distances. Plastic fibers are more flexible and easier to handle but are typically used for shorter distances.

Silica and Its Properties

Most glass fibers are made from silica (silicon dioxide). Silica is chosen because it's highly transparent, allowing light to pass through with minimal loss. It's also very durable, making it ideal for use in various environments.

Polymer Coatings

Polymer coatings are used to protect the fiber from physical damage and environmental factors. These coatings help maintain the integrity of the light signal and extend the life of the fiber optic cable.

Using the right materials ensures that fiber optics can perform well in a wide range of applications, from internet connections to medical equipment.

How Are Fiber Optics Manufactured?

The process of making fiber optics involves several steps, each crucial to creating a high-quality product. Here's how it's done.

Preform Fabrication

The process begins with creating a preform, a large glass rod. This preform is made by depositing layers of silica and other materials to form the core and cladding. The quality of the preform directly impacts the performance of the fiber optic.

Drawing the Fiber

Next, the preform is heated in a furnace until it becomes soft. It's then pulled (or "drawn") into a thin fiber. This fiber can be several kilometers long and must be uniform in diameter to ensure consistent performance.

Coating Application

Once the fiber is drawn, it's immediately coated with a protective polymer layer to shield it from physical damage and environmental factors. This coating is applied while the fiber is still warm and soft.

Quality Control

Throughout the manufacturing process, quality control measures are in place to ensure the fiber meets specific standards. This includes checking the fiber's diameter, testing for signal loss, and inspecting the coating for defects. High-quality fibers undergo rigorous testing to ensure they perform well in their intended applications.

The Bottom Line

Fiber optics are a game-changer in modern communication, providing fast, reliable, and high-capacity data transmission. Understanding what fiber optics are made of, their components, and their manufacturing process helps appreciate their role in today's technology. With ongoing advancements, fiber optics will continue to be at the forefront of data transmission innovations.

Call to Action

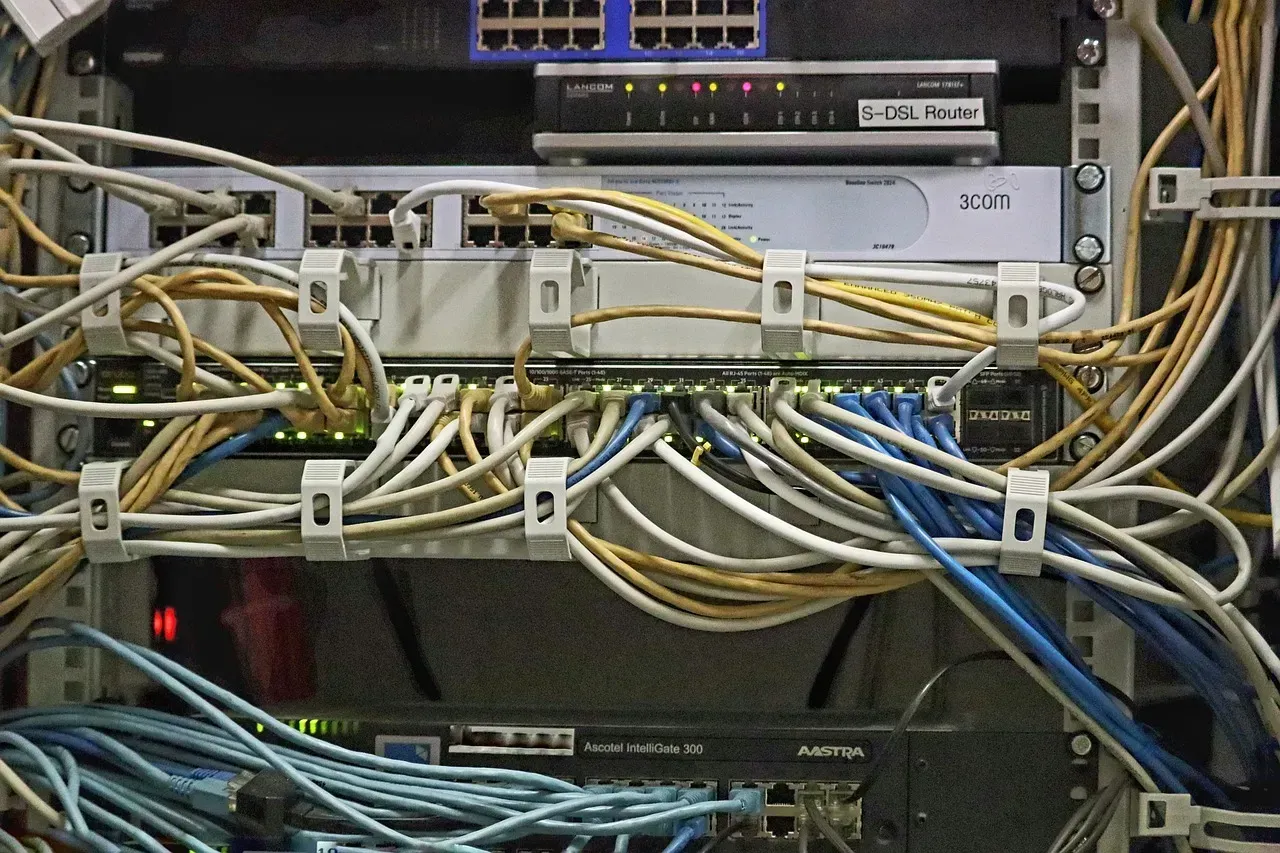

Looking for reliable fiber optic and cabling services in Charlotte? American Broadband Networks is your go-to provider. They specialize in:

- Broadband Networks

- Interior Cabling for Apartment Complexes

- Structured Cabling

- Fiber Optics

- Coaxial Cable Installation

- Wifi Installation and Management

- New Construction Internet

- Additional Network Outlets for Internet and Phones

Trust American Broadband Networks for all your cabling and fiber optic needs. Visit their website at abnnc.com to learn more and get started today!